Every business desires to be able to save operational costs. It is a top priority for some industries, like manufacturing, since many costs are associated with manufacturing processes. As a business, it is crucial to explore various ways to cut costs without compromising on your product quality and quantity.

You have come to the right place if you are looking for ways to keep your operations costs at the barest minimum.

Below are some tips.

Improve employee efficiency

Some business owners reduce employee pay when they want to cut costs. However, this will likely lead to employee dissatisfaction, high turnovers, and the eventual acquisition of unskilled workers. The best approach would be to increase labor efficiency.

Boosting your employee efficiency would not be easy, but worth the effort. It is possibly the most cost-effective technique for lowering production costs. You can achieve this by hiring efficient workers right from the beginning and offering incentives to staff to improve average production standard time. Matching jobs to skill sets is also recommended.

Reduce material costs

Cutting material prices or choosing cheaper suppliers is a straightforward technique to reduce production expenses. In reality, you may do this by modifying the design of your items and employing all of your available resources. It is advisable to understand the cost implication of using product components before selecting them. You can go for a simpler design that requires fewer raw materials.

Additionally, avoid throwing away any excess or leftover material, such as metal, paper, or cardboard. You can do a few things to cut costs by reducing waste. For instance, you can send them to the recycling facility or consider reusing them for a new product or selling them.

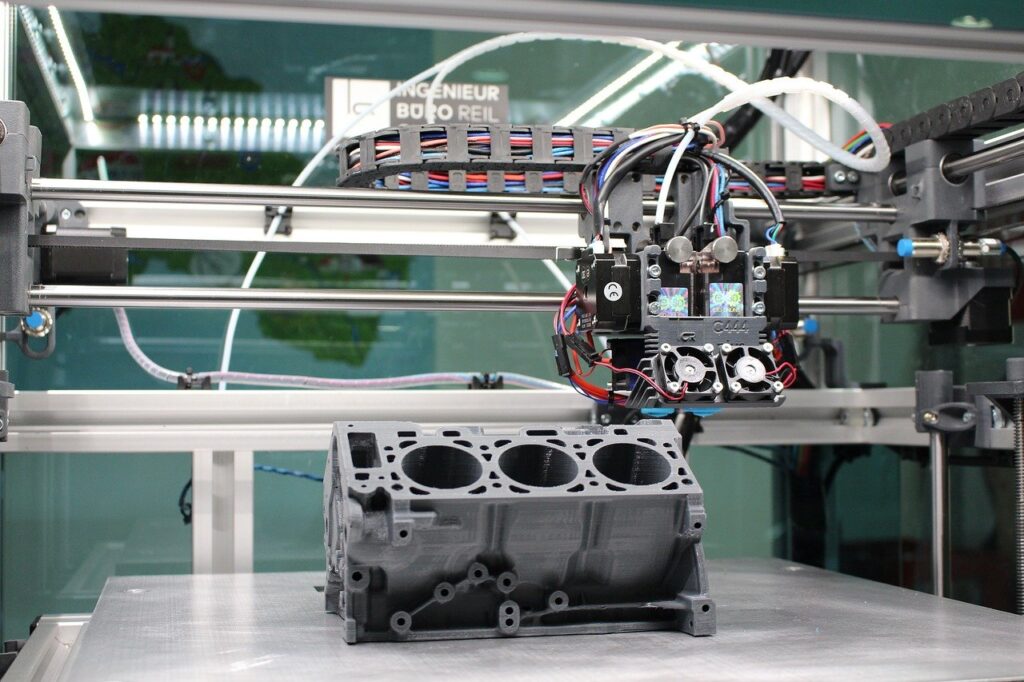

Use the right tools to optimize processes

The tools you choose may make all the difference, and they are considered to be among the critical production aspects. Using the right tools can help reduce waste and defects during different production stages.

For instance, a metal manufacturing company can use a Rockwell hardness tester to determine material hardness and suitability for the purpose. The testing can be useful for avoiding costly revision procedures and time-consuming defect replacement. It is common to see manufacturing businesses use old tools for their processes.

However, purchasing the correct, current tools can help reduce wasteful expenditures associated with overstaffing, excessive supply orders, and other concerns.

Revenue non-value-adding processes

Many operating methods are frequently innovated, and most processes are subject to periodic assessments to determine flaws. While looking for any deficiencies in your production methods, keep an eye out for needless, superfluous procedures in your production cycle that add little or no value to the products. These processes can be time and money-wasting. As a result, it can be useful to examine each level to determine whether a process is necessary for the current situation.

Every business strives to reduce operating costs since they may be a big burden on a business. While operational costs may differ depending on your business size, type or location, the above tips can be useful for getting a grip on your operational costs.