Nevertheless, this industry is typically dominated by automotive manufacturers and tech giants. For instance, both Samsung and Volkswagen are two of the largest companies in this sector.

The industry has become so massive in the last few decades, and a large part of this is down to the influx of technology seen throughout manufacturing enterprises. We have seen things from simple software implementations to full-on AI robots in manufacturing factories. The innovations are diverse, but just how beneficial have they been across the sector?

Let’s look at some of the undeniable advantages that technology has brought to manufacturing:

Improved productivity

The tech innovations throughout this sector have definitely had a positive impact on productivity and efficiency. Mainly, we can pinpoint a couple of key tech implementations that are responsible for this. Firstly, you have software that helps teams manage a manufacturing factory.

As shown on https://www.oeesystems.com/, the right software can let managers and employees control everything on a factory floor. You get so much data that lets you see where processes are slowing down and what you can do to improve. Effectively, the software has made it easier to manage and oversee a manufacturing company, thus driving more efficiency and productivity.

On the other end of the scale, you have things like AI automation on the factory floor. Humans have largely been replaced by robotic systems when it comes to actually doing manufacturing. Instead of a human cutting a part out of a sheet of metal, an AI-powered laser cutting device will do it. It’s pre-programmed, meaning it does it instantly without any stoppages, speeding up the whole manufacturing process.

Improved accuracy

Following on from that final point, technology on the manufacturing floor has meant that companies can be more accurate than ever before. These systems are pre-programmed to do a certain job, from Vickers hardness testers to injection moulding machines. And they all do to full accuracy every single time. It means that things are manufactured with a higher degree of accuracy than they used to be when human beings were in charge.

Think about it, you need a human to cut a shape out of a sheet of metal, and it can come out slightly different every single time. With computer systems and robotics at play, the exact same results are seen over and over again. The increased accuracy also impacts productivity as it means less time is wasted trying to get accurate replicas. Not only that but less time is wasted redoing any errors. As a result, this can lead to the next benefit…

Improved cost management

The benefit of improving productivity and accuracy means that the overall cost of manufacturing can decrease. For starters, because technology can take over from humans on the factory floor, it means that fewer employees need to be hired on a full-time basis. This shrinking of the worker pool means that less money gets spent on wages, benefits, and so on.

Moreover, the increased accuracy that technology brings will mean fewer errors are made. Human error can be extremely costly, just think about what happens if one mistake disrupts the manufacturing process. It can mean that numerous products are defective, rendering them useless. Loads of money is wasted on things that won’t work, and more has to be spent by remaking them. With technology, the chances of things like this happening are reduced dramatically. Thus, businesses are able to operate on tighter budgets with fewer expenses.

Improved quality

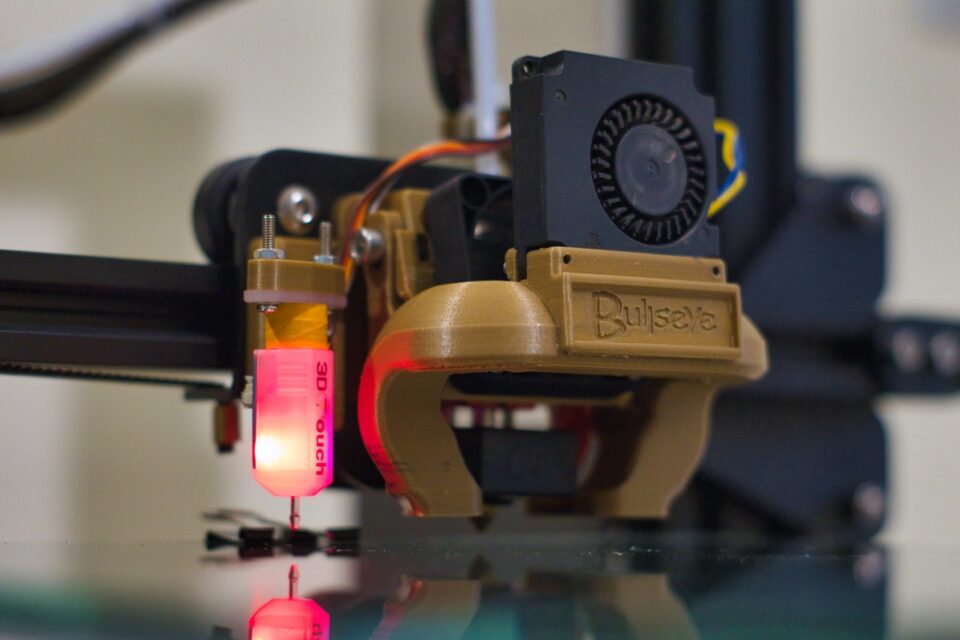

Overall, when you combine all of the previous benefits together, you end up with products that are manufactured to a higher quality than ever before. Technology makes it easier for companies to spot faults and iron them out before the product is mass-produced. You have things like 3D printing, virtual reality, and loads of software applications that can be used to develop prototypes and run tests. This lets companies reach a stage when they can be certain a product will be of the highest quality possible before clicking a button and getting it mass-produced for the market!

In reality, technology has transformed the manufacturing industry in many ways. Modern manufacturing companies now benefit from improved productivity, efficiency, accuracy, cost management, and quality.