In the evolving landscape of manufacturing, the quest for personalized, unique products has become a paramount goal for industries ranging from healthcare to consumer goods. This drive towards customization has been significantly fueled by advancements in manufacturing technologies, notably 3D printing, and plastic injection molding. Each method offers distinct advantages and challenges in the pursuit of tailor-made products, reshaping how businesses approach product design, production, and delivery.

What is 3D Printing?

The Basics of 3D Printing

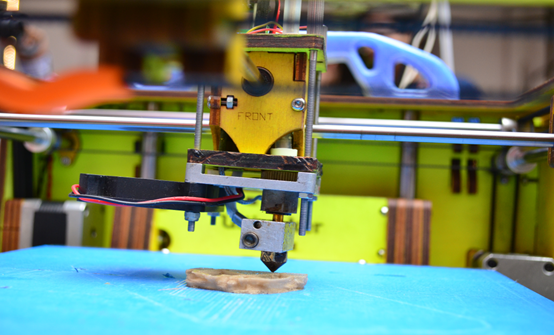

At its core, 3D printing, also known as additive manufacturing, is a process that creates physical objects from digital designs by layering materials. This technique has revolutionized prototyping and manufacturing across various sectors due to its flexibility and efficiency.

- Process: Digital models are sliced into thin layers which are then printed one atop the other.

- Types of 3D Printers: Includes Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

- Materials Used: Plastics, resins, metals, and more, varying by printer type.

Customization Advantages of 3D Printing

3D printing stands out for its unparalleled ability to produce complex, intricate designs that would be challenging, if not impossible, to create through traditional manufacturing methods. This capability opens up new avenues for personalization, from custom-fit medical devices to bespoke consumer products, all while maintaining a streamlined production process suitable for low-volume orders.

Limitations of 3D Printing for Customization

Despite its advantages, 3D printing faces limitations that can impact its effectiveness in certain customization scenarios:

- Material restrictions, limit the range of achievable product properties.

- Slower production speeds compared to traditional mass production techniques.

- Challenges in scaling up for large-volume manufacturing without significant cost increases.

What is Plastic Injection Molding?

Understanding Plastic Injection Molding

Plastic injection molding is a tried-and-true manufacturing process that produces parts by injecting molten plastic into a mold. It is favored for its ability to produce high volumes of parts with precision and uniformity.

- Process: Molten plastic is injected into a pre-designed mold, cooled, and then ejected as a solid part.

- Common Materials: Thermoplastics like ABS, polycarbonate, and polypropylene.

- Product Types: Ranges from simple items like bottle caps to complex automotive components.

For instance, 3ERP injection molding services offerings transcend mere solutions; they exemplify the integral role of technical proficiency and extensive experience in the plastic injection molding processes. With a strong reputation for consistently delivering premium products and services, 3ERP has established itself as a benchmark in the industry.

Customization Capabilities of Plastic Injection Molding

Customization in injection molding is largely achieved through the design of the molds, which, although costly and time-consuming to produce, can yield highly customized parts in large volumes. Material selection and the addition of colors or finishes post-production further enhance the customization potential.

Limitations in Customization with Plastic Injection Molding

Injection molding’s customization capabilities are not without their limitations:

- High upfront costs for mold design and manufacturing, making small runs expensive.

- Longer lead times due to the need for custom mold creation.

- Limited flexibility for design changes once production begins.

Comparing Customization Capabilities

Complexity and Design Freedom

How Does 3D Printing Promote Design Innovation?

3D printing empowers designers to experiment with complex geometries and structures, such as honeycomb patterns or intricate latticework, without the constraints of traditional manufacturing processes.

Can Plastic Injection Molding Support Complex Customizations?

While injection molding is somewhat limited by the complexity that can be achieved within a mold, advanced techniques, and tooling improvements have expanded its capabilities, allowing for a wider range of detailed features.

Speed and Flexibility in Production

Which Method Offers Faster Customization?

3D printing typically allows for quicker turnaround on customized products, especially for small batches, due to its direct from digital to physical process. Injection molding, however, can be faster for producing large quantities once the mold is created.

Cost Considerations for Custom Projects

Analyzing Cost-Effectiveness for Low vs. High-Volume Production

For small-scale custom projects, 3D printing often presents a more cost-effective solution due to low setup costs. Injection molding, conversely, becomes economically viable at higher volumes, where the initial cost of mold creation is distributed across a larger number of parts.

Material Options and Properties

How Do Material Choices Affect Customization?

The material selection significantly influences the customization possibilities and final product performance in both 3D printing and injection molding. While 3D printing offers a wide array of materials with unique properties, injection molding benefits from the use of highly durable thermoplastics suitable for mass production.

Enhancing Customization through Hybrid Approaches

Leveraging the strengths of both 3D printing and injection molding can lead to innovative manufacturing strategies. For example, 3D printed molds can be used for short-run injection molding, combining the rapid prototyping capabilities of 3D printing with the efficiency and material properties of injection molding.

Real-World Applications and Case Studies

Customization in the Medical Industry

- Patient-specific implants and prosthetics.

- Custom surgical tools and models for preoperative planning.

Customization in the Consumer Goods Sector

- Personalized gadgets and accessories.

- Bespoke home decor and furniture.

Automotive and Aerospace Custom Parts

- Lightweight, complex components for performance optimization.

- Custom tooling and fixtures for manufacturing processes.

Future Trends in Customization and Manufacturing Technologies

Emerging advancements in 3D printing and injection molding promise to further enhance their customization capabilities. Innovations such as AI-driven design optimization, new materials with enhanced properties, and more efficient production methods are set to redefine the limits of what can be achieved in customized manufacturing.

Making the Right Choice for Your Project

Key Factors to Consider When Selecting a Manufacturing Method

- The scale of production.

- Design complexity and customization level.

- Material requirements.

- Budget and timeline constraints.

Steps to Evaluate Your Customization Needs

- Define the project scope and requirements.

- Assess the feasibility of design options.

- Consider production volume and cost implications.

- Select the manufacturing process that best aligns with your project goals.

Conclusion

In the realm of manufacturing, the debate between 3D printing and plastic injection molding for customization reflects a broader conversation about innovation, efficiency, and the future of production. While each method has its strengths and limitations, the choice ultimately hinges on the specific needs of the project at hand. As technology continues to evolve, so too will the capabilities and applications of these manufacturing giants, promising an exciting future for customization in all areas of industry.